ABOUT US

ABOUT US

Who are Tricogen?

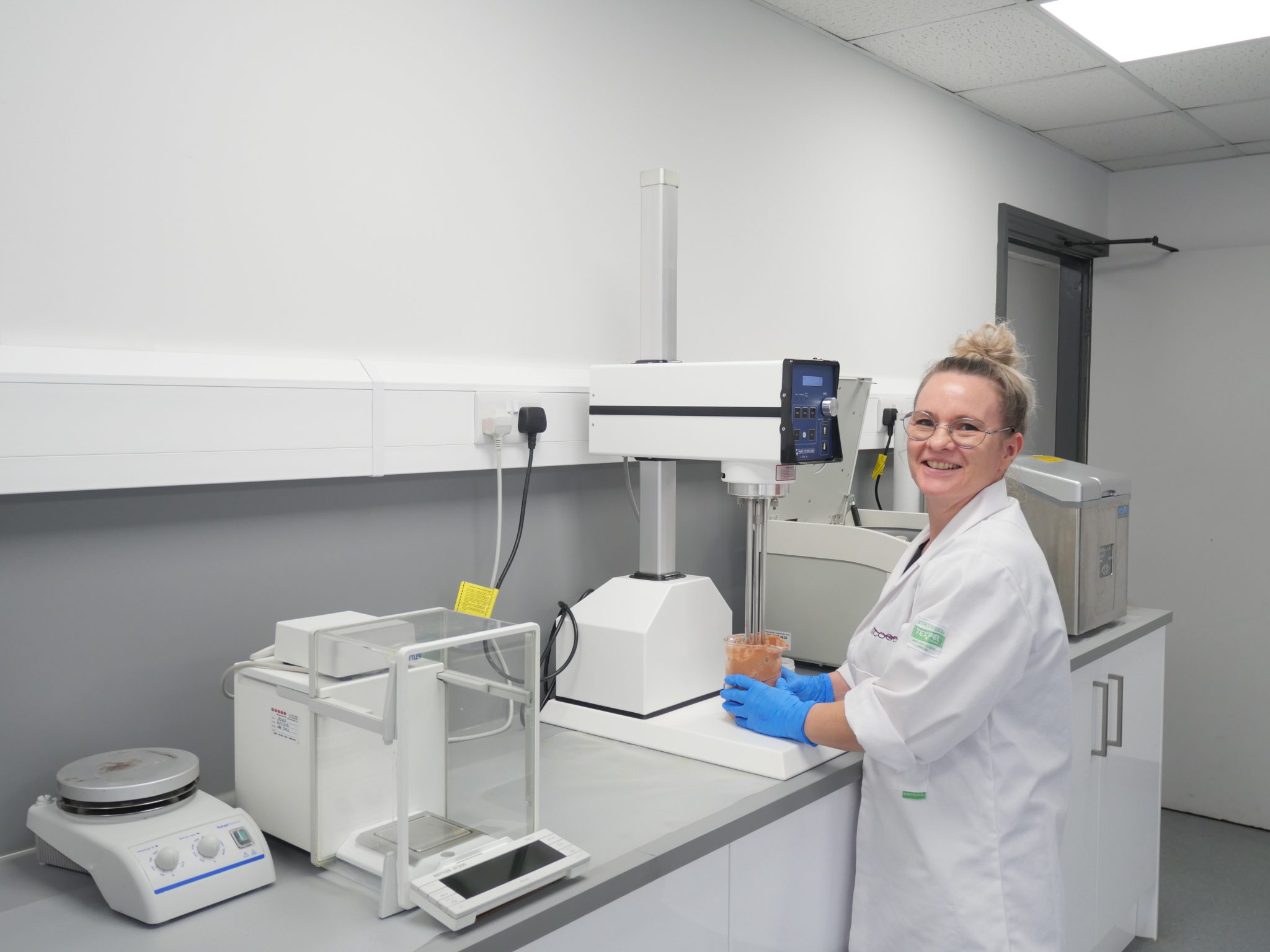

Tricogen are a family owned, specialist bespoke, state-of-the-art manufacturing and production facility with capacity to produce up to 6 million 1 litre bottles per year.

Our highly skilled team have a vast wealth of knowledge and experience and are committed to delivering continual product and manufacturing development. They are dedicated to delivering customer satisfaction.

- Family owned business established 1946

- Specialist modern plant and facilities

- Largest independent producer of peroxide products in Europe

The Tricogen Process

A flexible, enthusiastic and skilled team allied to state-of-the-art specialist plant means we can design, formulate, manufacture and fill to meet every need.

We take your concept from idea to shelf and from brief to reality.

INITIAL BRIEF

TESTING & COMPLIANCE

BRANDING

DESIGN & PRODUCTION

Why choose us?

Tricogen’s continual evolution and investment in new technology and know-how to meet the needs of our clients’ coupled with our proven ability to turn their concepts and ideas into profitable realities keeps us at the forefront of our industry.

Dedicated Business Development team

Our Dedicated Business Development team is an integral and key cog in Tricogen’s machine.

They are responsible for delivering our shared commitment to ‘getting it right first time’– for customers and Tricogen. Working closely with all departments to ensure that we always meet your specific requirements.

- Professional support

- High-quality consultations

- Best specialists

How We Got Here

The Beginning

Elias had a son, Solomon Abraham Sliufko, who is known to have made his living selling furniture to hairdressers in Darlington. He also worked for Nestlé, which brought out one of the first ever perm lotions, and still has a stake in L’Oréal today.

Ray and Company LTD

Growth & Expansion

New Product Lines

Four Generations of Success

Tricogen Rebranding

COVID-19 Respose

Since the coronavirus pandemic, the company’s output of the product has rocketed from five tons a year to 100 tons a week, and there is enough demand to treble production.